We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for panel furniture production line for woodworking cabinets, We hope to establish far more organization associations with consumers all over the globe.

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for , With good quality, reasonable price and sincere service, we enjoy a good reputation. Items are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

EXCITECH SMART FACTORY

We strive to make your production smarter,

faster and more cost-efficient with minimum human labor

required

width="1000" height="385" alt="SF_02.jpg" />

width="1000" height="385" alt="SF_02.jpg" />

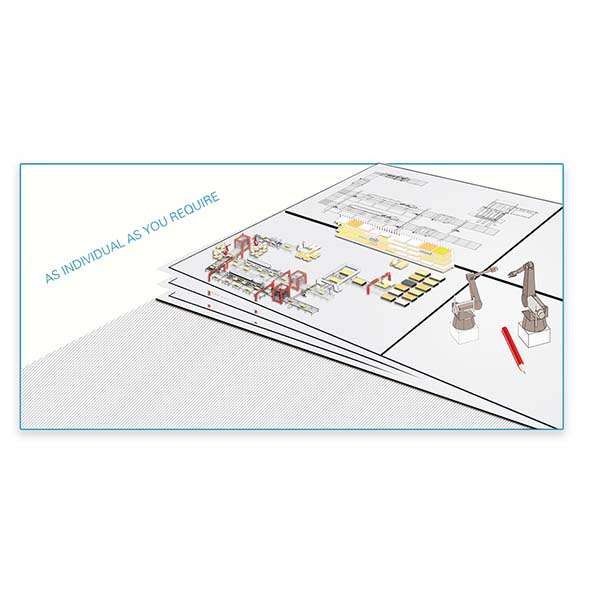

We understand different applications require different manufacturing equipments.

Thus we personalize the projects so each investors can produce with the right

technologies

that match their exact needs.

width="1000" height="426" alt="SF_04.jpg" />

width="1000" height="426" alt="SF_04.jpg" />

Automated Panel Furniture Production

Line

width="1000" height="265" alt="SF_06.jpg" />

width="1000" height="265" alt="SF_06.jpg" />

height="579" alt="SF_07.jpg" />

height="579" alt="SF_07.jpg" />

height="511" alt="SF_08.jpg" />

height="511" alt="SF_08.jpg" />

Application

Examples:

A.

One nested-based CNC, one drilling machine, with one edgebander

width="999" height="134" alt="SF_10.jpg" />

width="999" height="134" alt="SF_10.jpg" />

B.

Two nested-based CNCs, three drilling machines, with two edgebanders

width="1000" height="196" alt="SF_11.jpg" />

width="1000" height="196" alt="SF_11.jpg" />

C.

Fully automated production line with four edgebanders

width="1000" height="188" alt="SF_12.jpg" />

width="1000" height="188" alt="SF_12.jpg" />

Material

Handling Devices:

(To be applied according to the factory

layout and customer requirements)

width="1000" height="636" alt="SF_13.jpg" />

width="1000" height="636" alt="SF_13.jpg" />

Automated

Cabinet Door Production Line

<img

src="//15754404.s21i.faiusr.com/2/ABUIABACGAAguf295AUo9Lb0oQYw6Ac4iAQ!800x800.jpg" alt="SF_15.jpg" style="width:800px;height:416px;" /><img

src="//15754404.s21i.faiusr.com/2/ABUIABACGAAgvf295AUoyuD7rQQw5wc4gQQ.jpg" width="999" height="513" alt="SF_17.jpg" /><img

src="//15754404.s21i.faiusr.com/2/ABUIABACGAAgvf295AUoqq7FgwUw5wc49gQ.jpg" width="999" height="630" alt="SF_18.jpg" />

Smart factory project can be sold

as a whole or as separate production cells.

Nesting Cell Scenarios

_mi="AGUIJBIA" _mu="pd.jsp?pid=36"> width="1000" height="336" alt="003.jpg" title="003.jpg" />

width="1000" height="336" alt="003.jpg" title="003.jpg" />

Edgebanding Cell Scenarios

_mi="AGUIJRIA" _mu="pd.jsp?pid=37"> width="1000" height="332" alt="004.jpg" />

width="1000" height="332" alt="004.jpg" />

Drilling Cell Scenarios

_mi="AGUIJhIA" _mu="pd.jsp?pid=38"> width="1000" height="657" alt="005.jpg" />

width="1000" height="657" alt="005.jpg" />

Production Facility

In-House Machining Facility

Quality Control & Testing

Pictures taken at Customer’s Factory

- We provide 12 months warranty for the machine.

- Consumable parts will be replaced free during the warranty.

- Our engineer could provide technology support and training for you in your country, if necessary.

- Our engineer could service for you 24 hours online, by Whatsapp,Wechat,FACEBOOK, LINKEDIN,TIKTOK,cell phone hot line.

The cnc center is to be packed with plastic sheet for cleaning and damp proofing.

Fasten the cnc machine into the wood case for safety and against clashing.

Transport the wood case into the container.