Is the same with your CNC Nesting machine?

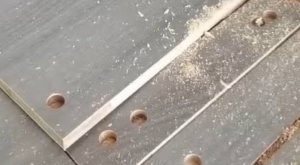

Excitech researches and develops a dust-free system independently,and there is no obvious dust during the process of Cnc Nesting machine.

After the processing is finished,the surface and backside of panel,the inside of groove,and the ground around the machine are clean and dust-free.

Excitech adopts metal machine tool testing standards,uses ball bar to diagnose the dynamic accuracy of the CNC Nesting machine quickly and accurately,and uses laser interferometer to measure the linear position,speed,angle,flatness,straightness,parallelism and perpendicularity of the CNC Nesting machine,to ensure that the precision of the Cnc Nesting machine is ±15 (±0.15mm).

◆ Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time.

◆ World‘s first class components--Italian high-frequency electro spindle, controller system and drill bank, German helical rack and pinion drives, Japanese self-lubricating and dust-proof square linear guides and high precision planetary gear reducers, etc.

◆ Truly versatile--nesting, routering, vertical drilling and engraving all in one. It is well-suited for panel furniture, office furniture, cabinets production.

Our pursuit and corporation intention is to "Always satisfy our client requirements". We continue to develop and style remarkable high-quality items for each our outdated and new shoppers and accomplish a win-win prospect for our customers likewise as us for China CNC Nesting Machine, Nesting Cnc Router, We present OEM services and replacement parts to meet the varying needs of our customers. We supply competitive price for quality goods and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

◆ Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time.

◆ World‘s first class components--Italian high-frequency electro spindle, controller system and drill bank, German helical rack and pinion drives, Japanese self-lubricating and dust-proof square linear guides and high precision planetary gear reducers, etc.

◆ Truly versatile--nesting, routering, vertical drilling and engraving all in one. It is well-suited for panel furniture, office furniture, cabinets production.

APPLICATIONS

Wooden door, cabinet, panel furniture, closet, etc. Suitable for standard or bespoke production.

| SERIES |

E4-1224D |

E4-1230D |

E4-1537D |

E4-2128D | E4-2138D |

| Traveling Size | 2500*1260*200mm | 3140*1260*200mm | 3700*1600*200mm | 2900*2160*200mm | 3860*2170*200mm |

| Working Size | 2440*1220*70mm | 3080*1220*70mm | 3685*1550*70mm | 2850*2130*70mm | 3800*2130*70mm |

| Table Size | 2440*1220mm | 3080*1220mm | 3685*1550mm | 2850*2130mm | 3800*2130mm |

| Loading & Unloading Speed | 15m/min | ||||

| Transmission | XY Rack and Pinion Drive,Z Ball Screw Drive | ||||

| Table Structure | Vacuum Table | ||||

| Spindle Power | 9.6/12 kW | ||||

| Spindle Speed | 24000r/min | ||||

| Traveling Speed | 80m/min | ||||

| Working Speed | 25m/min | ||||

| Tool Magzine | Carousel | ||||

| Tool Slots | 8/12 | ||||

| Driving System | Yaskawa | ||||

| Voltage | AC380/3PH/50HZ | ||||

| Controller | Syntec/OSAI | ||||

- We provide 12 months warranty for the machine.

- Consumable parts will be replaced free during the warranty.

- Our engineer could provide technology support and training for you in your country, if necessary.

- Our engineer could service for you 24 hours online, by Whatsapp,Wechat,FACEBOOK, LINKEDIN,TIKTOK,cell phone hot line.

The cnc center is to be packed with plastic sheet for cleaning and damp proofing.

Fasten the cnc machine into the wood case for safety and against clashing.

Transport the wood case into the container.