product center

about our company

WE DESERVE YOU

Factory area: The headquarters is located in Jinan National High tech Development Zone, covering an area of 48000 square meters. Guangdong Xinghui CNC is located in Zhaoqing National High tech Zone and was put into operation in June 2023. Currently, the first workshop has a single floor area of 16000 square meters and a total of 48000 square meters in three floors. The second workshop under construction has a single floor area of 8000 square meters and a third floor area of 24000 square meters, with a total workshop area of 72000 square meters

Product quality: Automated CNC machining technology, triple testing to ensure excellent machine processing, international brand accessories, stable performance.

-

49patent

-

49awards

-

40copyright

-

49+country

our advantage

-

quality

Automated CNC machining process, triple inspection ensures excellent machining, international brand configuration, stable performance. -

experience

Years of production experience, products penetrate the non-metal processing field, covering every industrial city. -

technical

Help customers provide product processing solutions, technical guidance, software training, after-sales maintenance, etc. -

service

In Excitech, we are not just a manufacturing company. We are business consultants and business partners.

customer reviews

application cases

-

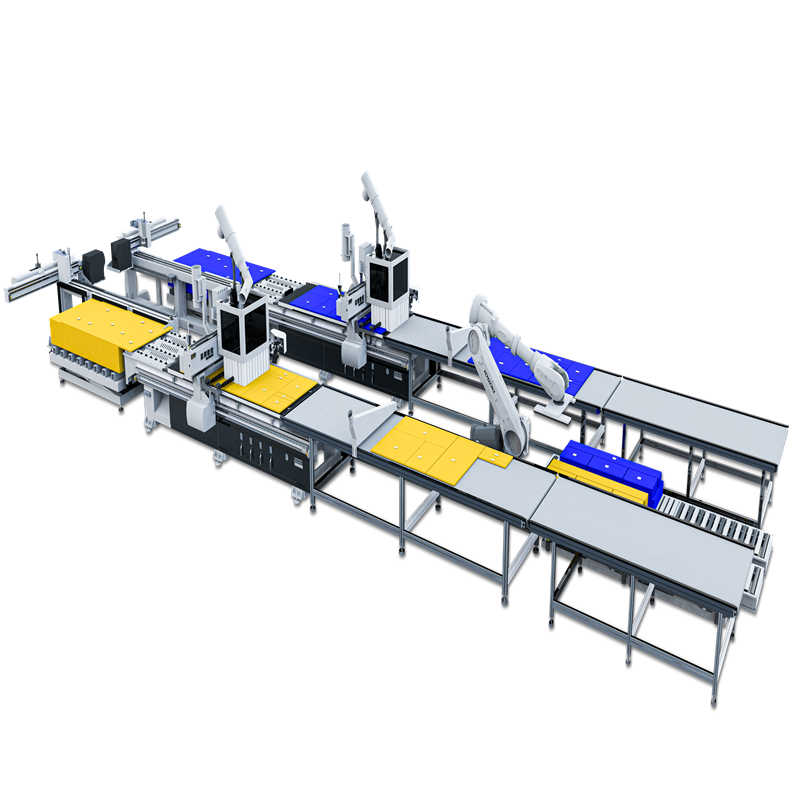

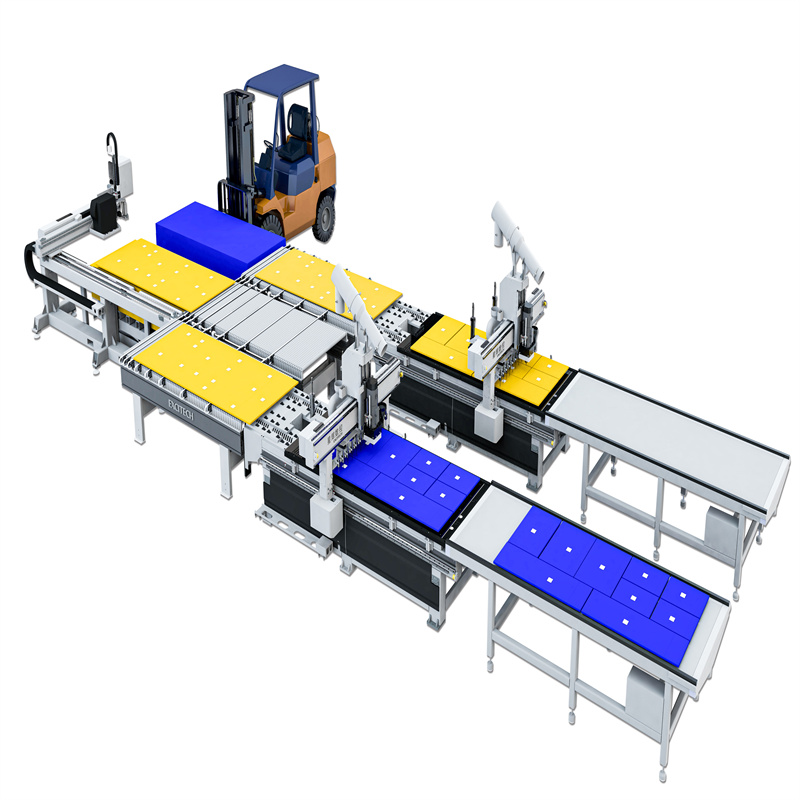

Industry 4.0 Smart Factory Production Solution

EXCITECH adheres to the guiding ideology of attaching equal importance to R&D and quality, increases investment in R&D, attaches importance to product quality and user experience, studies, explores, studies and practices in the field of intelligent manufacturing, independently develops the MS production management system and central control software that meet the market demand based on more than ten years of experience in R&D and production of numerical control equipment, vigorously promotes the application of technical information means, and combines automation hardware to create a customized furniture flexible smart factory project as an advanced technology display of EXCITECH, which is interconnected and intelligent, and promotes the furniture industry to realize information data.Nowadays, furniture production has got rid of the isolated stand-alone mode in the past, and has become an IOT mode from planning to design, production, process monitoring, full circulation of information and full coverage. The application of intelligent robots has been increased from material transmission to automatic sorting, and the data information of each link is collected, analyzed and integrated by the master control system, thus realizing the scale, industrialization and informatization of customized production.

-

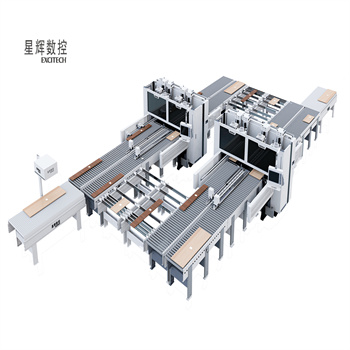

Dust free high-speed CNC cutting and machining center

EXCITECH wood nesting machine structure of the machine is exquisite, achieving a win-win of speed and precision. Standard double spindle in the machine, can be used for cutting and engraving, and it can also clamp different tools for different function. With the push device, the wood panel can be unloading from the processing table automatically, convenient for the operator to take the panel. At the same time, double working station processing without interruption, can save time for completion and greatly improve production efficiency saving processing time and improving processing efficiency greatly. Meanwhile, the machine also can be equipped with auto feeding platform.The machine is equipped with vertical boring unit for vertical punching in the panel. It can be docked with EXCITECH cabinet software, optimized materials, can be flexible and cost-effective.

-

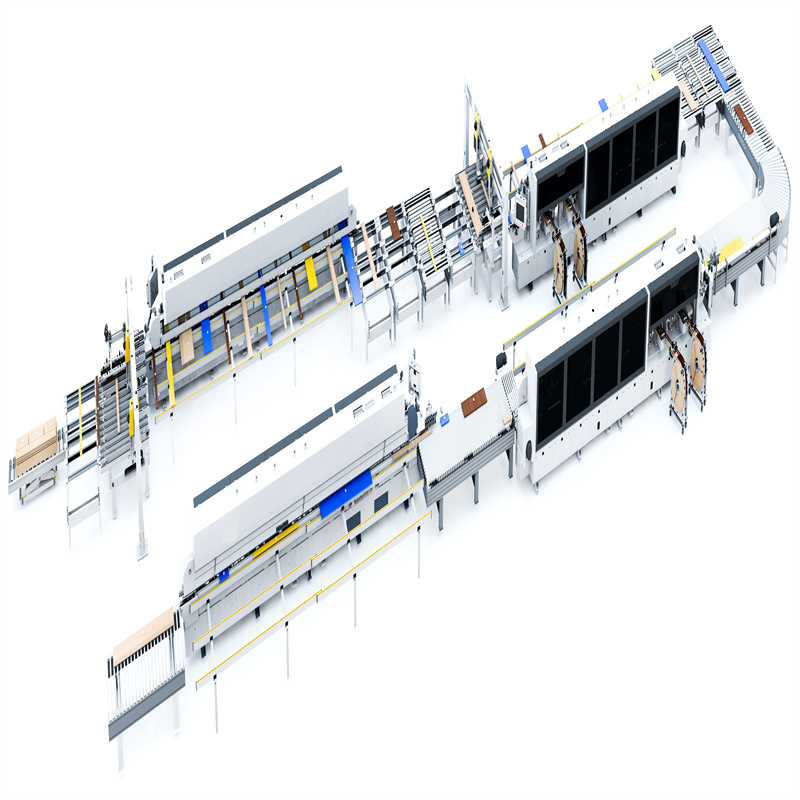

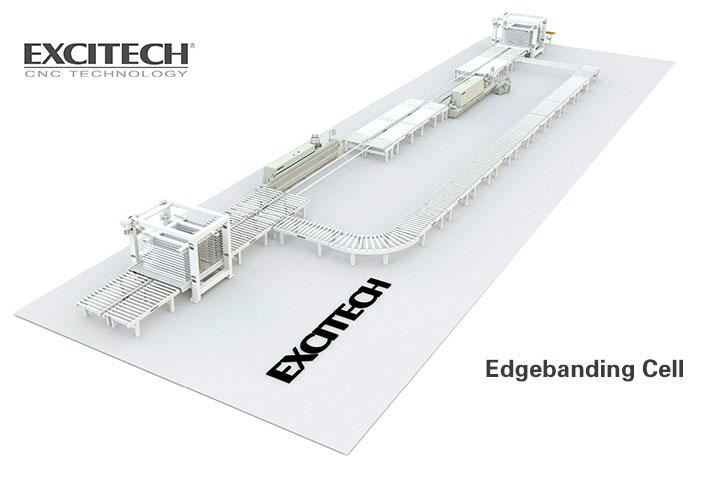

High speed flexible fully automatic edge sealing solution

Edge banding work is an important process in the manufacture of panel furnture. The qualit of the edge banding directly affects the qualit, price and grade of the product. By edge banding, EXCITECH edgeband machine can improve the appearance qualit of the furniture machineure, avoid the corners damage and the veneer layer pick up or peel off, and at the same time, EXCITECH edgeband machine can play the role of waterproofing, close the release of harmful gases and reduce deformation during the transportation and using process. The raw materials used by the panel furniture manufacturers are mainly for particleboard, MDF and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips. The structure of the edge banding machine mainly includes the fuselage, various processing components and control systems. EXCITECH edgeband machine is mainly used for edge sealing of panel furniture. EXCITECH edgeband machine is characterized by automation, high efficiency, high precision and aesthetics. EXCITECH edgeband machine has been widely used in panel furniture manufacturers.

-

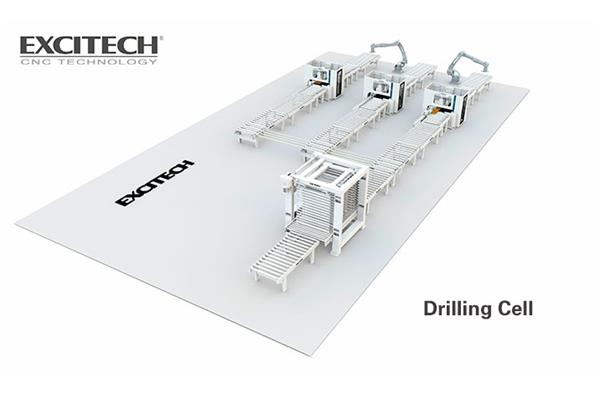

High speed universal CNC drilling center

Six-sided drilling machine is mainly used for horizontal,vertical drilling and slotting in various types of artificial panels, with small power spindle for slotting, solid wood panels, etc. Simple operation, fast drilling processing speed, with small spindle slotting, it is suitable for processing all kinds of modular cabinet-type furniture. Six-sided drilling machine can fix the work piece in one clamping and multi-face machining. It simplifies the overall machining process of the work piece, simplifies the process, improves the machining efficiency. It has also completely solved the problem that the complicated work piece needs the error caused by multiple clamping, which reduces the work difference and improves the machining precision.

-

Five axis three-dimensional machining solution for composite materials

E10 machine is a five-axis processing center with OSAI controller—designed for the most demanding processing requirements, maximum precision, faster production. All parts of the machine are made of world top components, such as Italian imported OSAI control system, Yaskawa servo motor and Japan THK linear guide. Easy profiling on large work piece, well suited for 3D curved surface processing. Working speed, travelling speed and cutting speed can all be controlled separately, dramatically improve productivity.

-

Wooden doors/solid wood/advertising processing solutions

The heavy duty machine with 8-slot carousel tool magazine, suitable for gravity cutting, with wide function such as routing, drilling, cutting, side milling, edge chamfering, etc. Boring aggregate can be optional. Vacuum table with great absorption strength – adsorb different areas of materials, also can use fixtures to hold various shaped materials with fixture, which is flexible and convenient. At the same time, the drilling bank is optional according to the customer’s needs.